Our History

Formed by innovation, dedication, and capable people, just like our products and services.

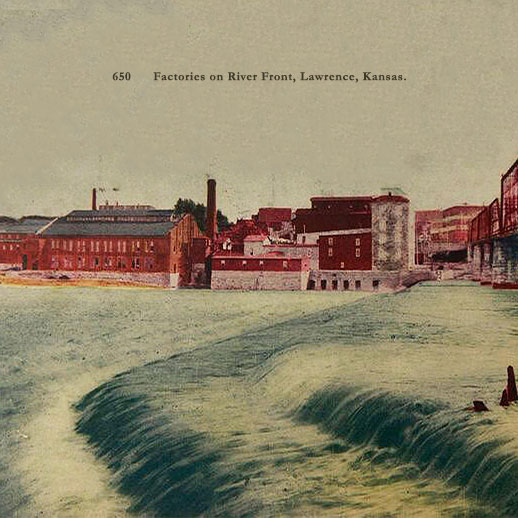

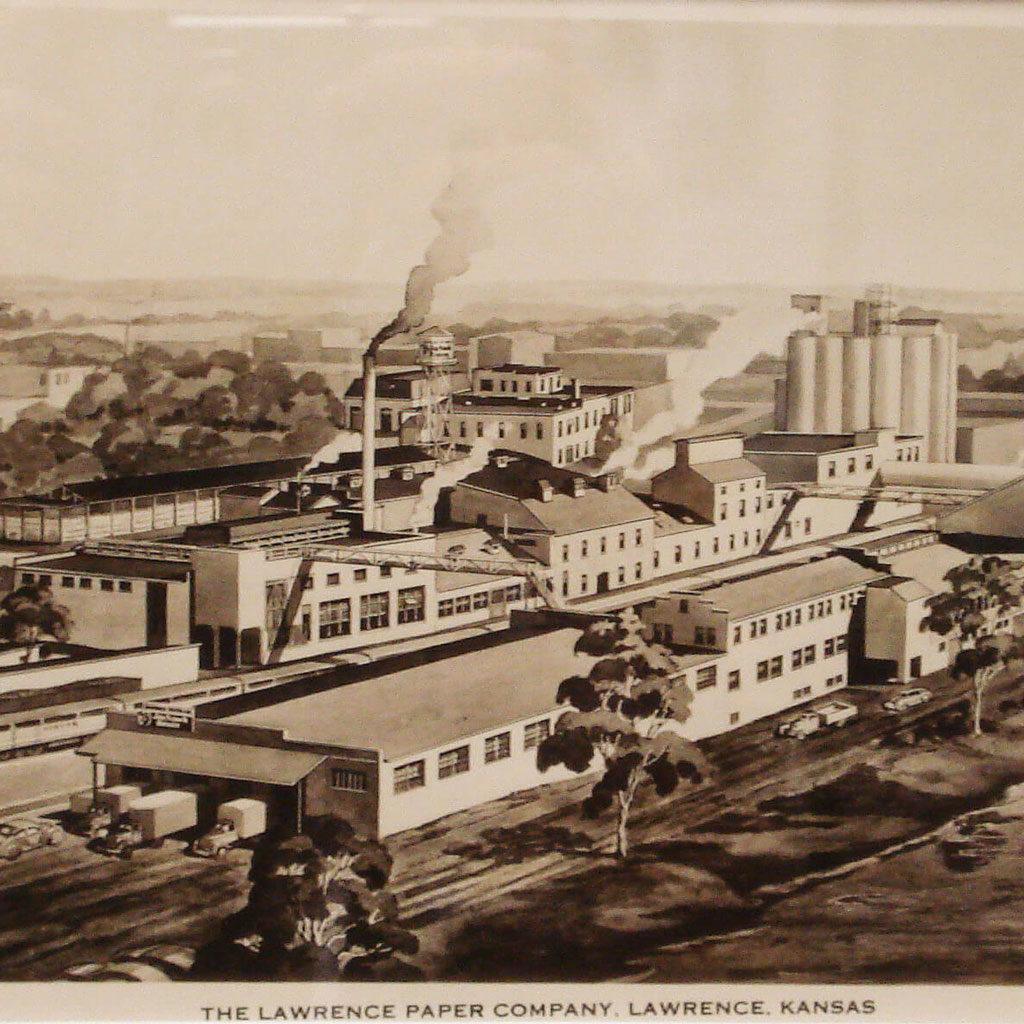

1870 — 1874

In the 1870s, Lawrence, Kansas was beginning to emerge as a growing industrial center in the region. With the construction of a dam across the Kansas River in 1874, new opportunities arose to utilize this fresh source of power.

1882

Incorporated

On October 16, 1882, articles of incorporation were filed for Lawrence Paper Company, naming Justin DeWitt Bowersock as president of the company. Thus began a long-lasting relationship with the community that laid the foundations for an enduring and prosperous company.

1882 — 1883

A paper mill, the first constructed west of the Mississippi, soon followed that made wrapping paper from straw. The straw was cooked for 18 hours in vats on the top floor of the mill and then chopped thoroughly. The material was taken to the lower floor and put into water-filled vats containing wire mesh cylinders. As the water was pumped out, the straw pulp would collect on the wire mesh. Then the pulp was carefully peeled from the mesh and put through a series of rollers, the last of which was steam-heated to help dry the paper. After the paper was trimmed and bundled, it was ready for shipment.

1884

By 1884, the plant was producing about five tons of paper a day, most of it shipped to Kansas City where distillers used it to wrap whiskey bottles. Straw paper also was used for egg case fillers and flats.

1885

Besides plant workers, the company employed several haulers who collected straw throughout the area with horse-drawn wagons. By 1895, Lawrence Paper Company was buying all the straw it could find within 30 miles of Lawrence.

1887

In 1897 the Lawrence plant began to experiment with making paper boxes, as a new industry was beginning to emerge.

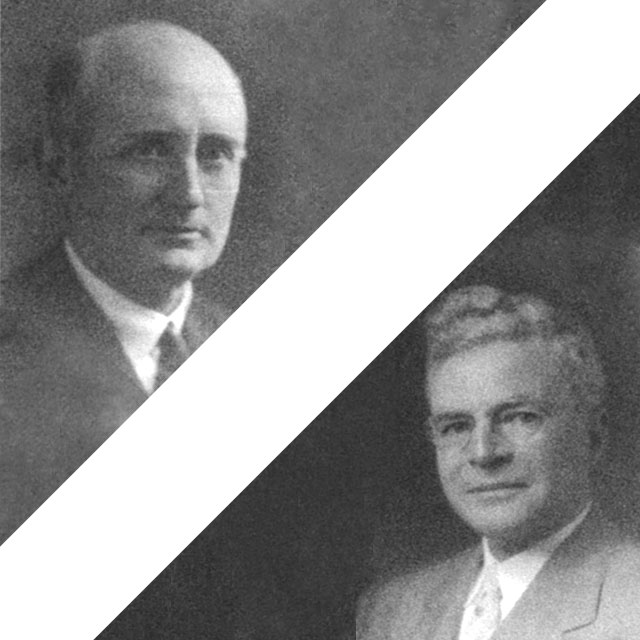

1898 — 1901

In 1898 Justin Bowersock was elected to the first of his four terms as U.S. Congressmen, and in 1901 he turned management of the company over to his sons-in-law, Irving Hill as Manager and Paul Dinsmoor as assistant Manager. Hill, who later would be called “the Sage of Kansas” by his peers in the industry, focused his energy on developing both new products and new markets for the paper mill. Hill was about to chart the course that would make Lawrence Paper Company a leader in a new industry.

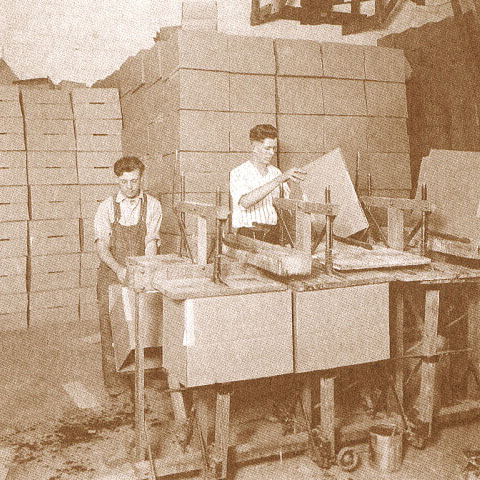

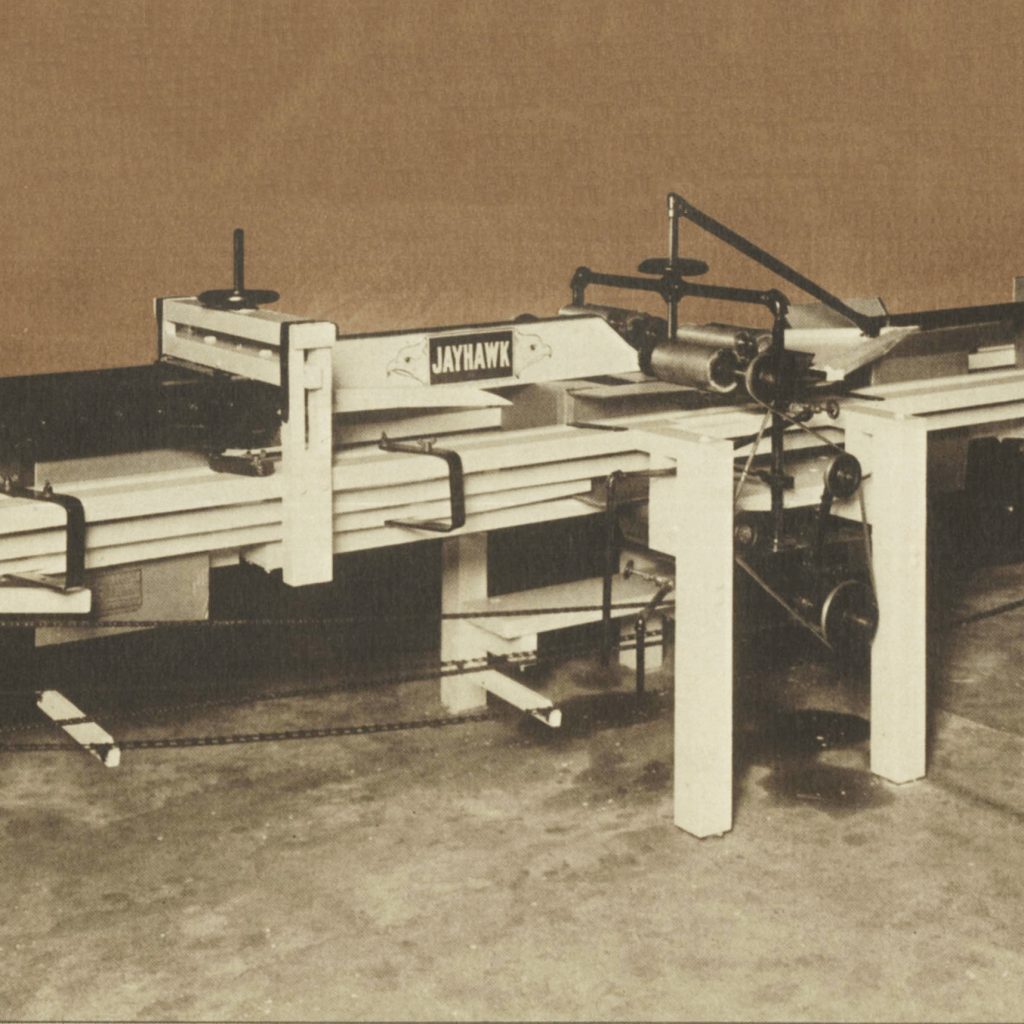

1901 — 1904

Since the company was supplying whiskey distillers in Missouri with corrugated paper wrappers, Hill decided to try selling the distillers corrugated paper boxes. Making corrugated boxes, under the brand name Jayhawk, required the company to create new equipment. But the process was cumbersome and required much hand-work.

1905

Hill sold Jayhawk boxes to the whiskey distillers, and then went to work to sell the corrugated paper boxes to Ball Brothers Co. of Muncie, Indiana, makers of the famous mason jars used in home canning. After a one year trial comparing jar breakage in Jayhawk boxes to traditional wooden boxes, Ball was convinced and by 1905 they were shipping their glass jars exclusively in Jayhawk boxes.

1910 — 1914

Hill next decided to go after the largest shipping market available at the time: canned food. Hill hired an engineer named Mosher to design an automatic sealing machine to eliminate the need for hand-sealing that was making paper boxes cost-prohibitive. Lawrence Paper Company patented the device, but Hill gave the patent to the new trade association he had formed so that the whole industry would benefit from the invention.

1910 — 1914

The automatic sealer and the corrugated paper box together made possible the production line in food canning factories. It was a revolution for the canning industry.

1910 — 1914

Lawrence Paper Company also designed corrugated paper boxes which were sturdy enough to successfully serve as shipping containers for canned food. This led to the creation of its new slogan: “Jayhawk boxes carry the load to the end of the road.”

1914 — 1917

In 1914 the company sold 40,000 can cases. The next year, it sold 100,000. By 1917, Lawrence Paper Company was making a million can cases a year.

1932

In 1932 the company produced Freezurboard, a moisture-resistant paperboard originally designed for shipping eggs, but which also proved valuable for shipping meat products. The company also designed a box with improved ventilation for shipping baby chicks. Those two products were the company’s mainstay through the depression.

1941 — 1945

At the outbreak of World War II the manufacturing of corrugated paper boxes was declared an unessential industry. But Lawrence Paper proved its value to the war effort, using its old contacts with the food canning industry to market boxes to the armed services, for itself and for other box makers.

1945 — 1957

After the war, the economics of the industry were changing and it was no longer cost-effective to try to serve customers more than 200 miles from the point of production. In 1957 the company established Jayhawk Boxes Inc. in Fremont, Nebraska in order to better serve its customers in the Northern Plains.

1957

Justin Hill Sr. assumed the presidency of the company in 1957 from his father, who continued to take an active interest in the operation of the company until his death.

1969

Alan Hill, Justin Sr.’s son, was named vice president of the company in 1969 and began work on plans for building a new production plant in, what was at the time, the northwest reaches of Lawrence.

1971 — 1975

The move from the three-story plant on the banks of the Kaw River to the new plant was completed in 1971. The manufacture of paper continued at the old location until it was closed in 1975, ending a 93-year old tradition, but allowing for the expansion needed to serve the growing market.

1975

Justin Hill Jr. joined the company in 1975 as secretary-treasurer and was in charge of the computer system that has become one of the most sophisticated systems used throughout the boxboard industry.

1978

Justin Hill Sr. resigned the presidency in 1978 and was succeeded by the fourth generation of the family to run the company, his son Alan Hill.

1986

Perry Manufacturing was built in 1986 as a result of one of Alan Hill’s hunting trips with a major customer. The customer mentioned that he wished he had an answer for the challenge of utilizing plastic to better suit their packaging needs. Alan took that concept and developed yet another solution to meet customers’ needs, starting the Perry Manufacturing Company and entering the thermoform business. Based in Perry, Kansas, it became one of the largest custom thermoformers in the Midwest, until it was sold in 2008.

2000

The Packaging Café was formally introduced in 2000, offering customers a one-stop packaging approach for all their packing needs. Combining resources with Lawrence Paper Company, The Café packs customers’ product at the same location the packaging is manufactured, improving speed, efficiency, and providing another value-added service to its customers.

2004

In 2004, after the passing of Alan, Justin Hill Jr. assumed the role of President of Lawrence Paper Company. He focused his efforts on upgrading the plant’s machinery to a world-class standard, improving the efficiency and quality in which customers are served. Nearly $20 million of capital improvements have been made to the production floor, bringing some of the best corrugated machinery in the world to the Midwest.

2012

Seeking to expand its reach into central and western Kansas, Lawrence Paper acquired American Packaging Company on January 1, 2012. Founded in 1987 by Dave Claxton, American Packaging brings a talented array of people, a broad lineup of machinery, and a set of extensive customer relationships to the Lawrence Paper family.